|

Marcus Str. Husband, flight sim pilot, IT specialist About | Tweets | Categories |

||

|

Attention owners of these IP addresses! I have reported you for deliberate attempts to acquire illegal access to my server. Have a nice day :) |

||

|

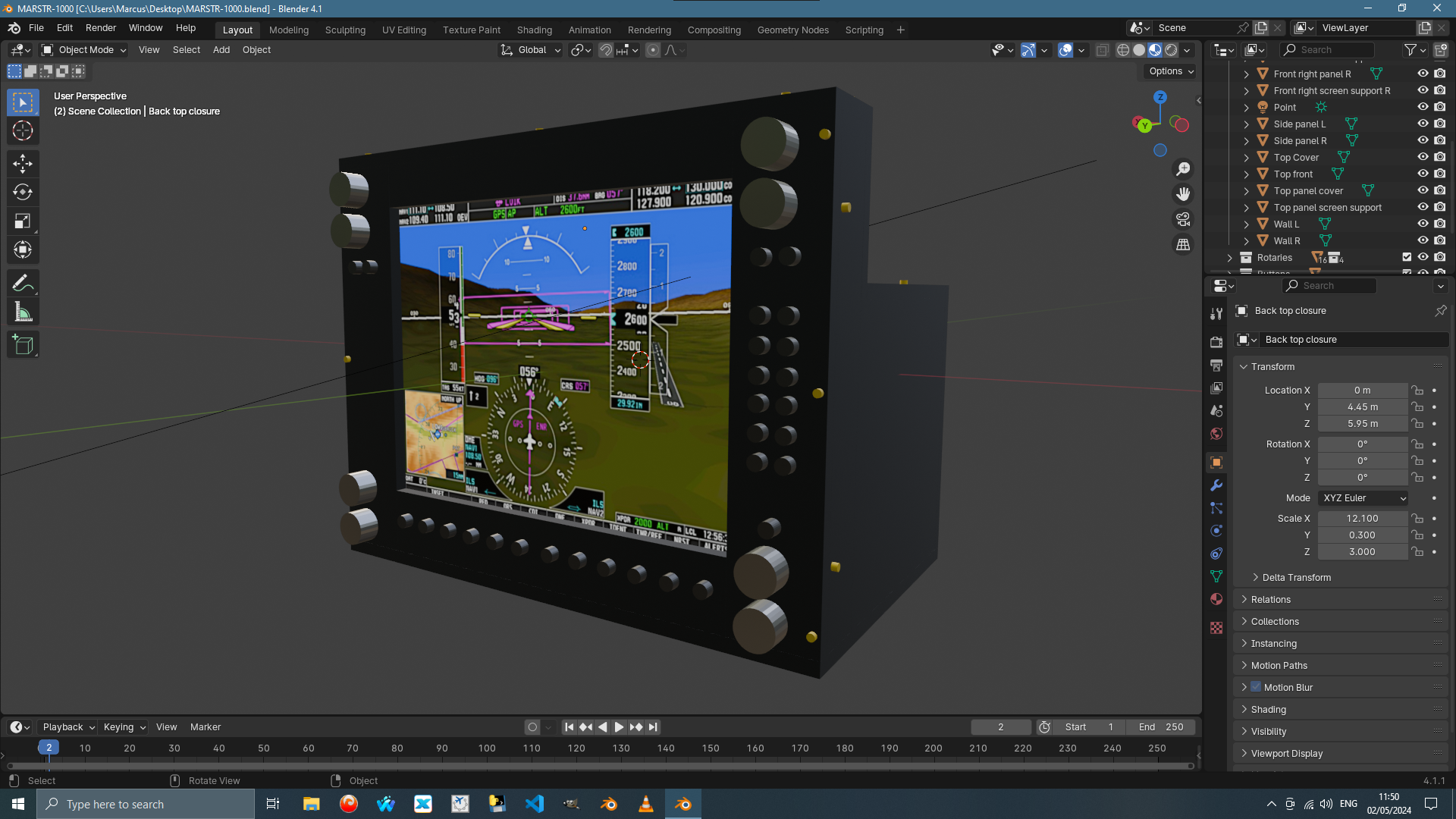

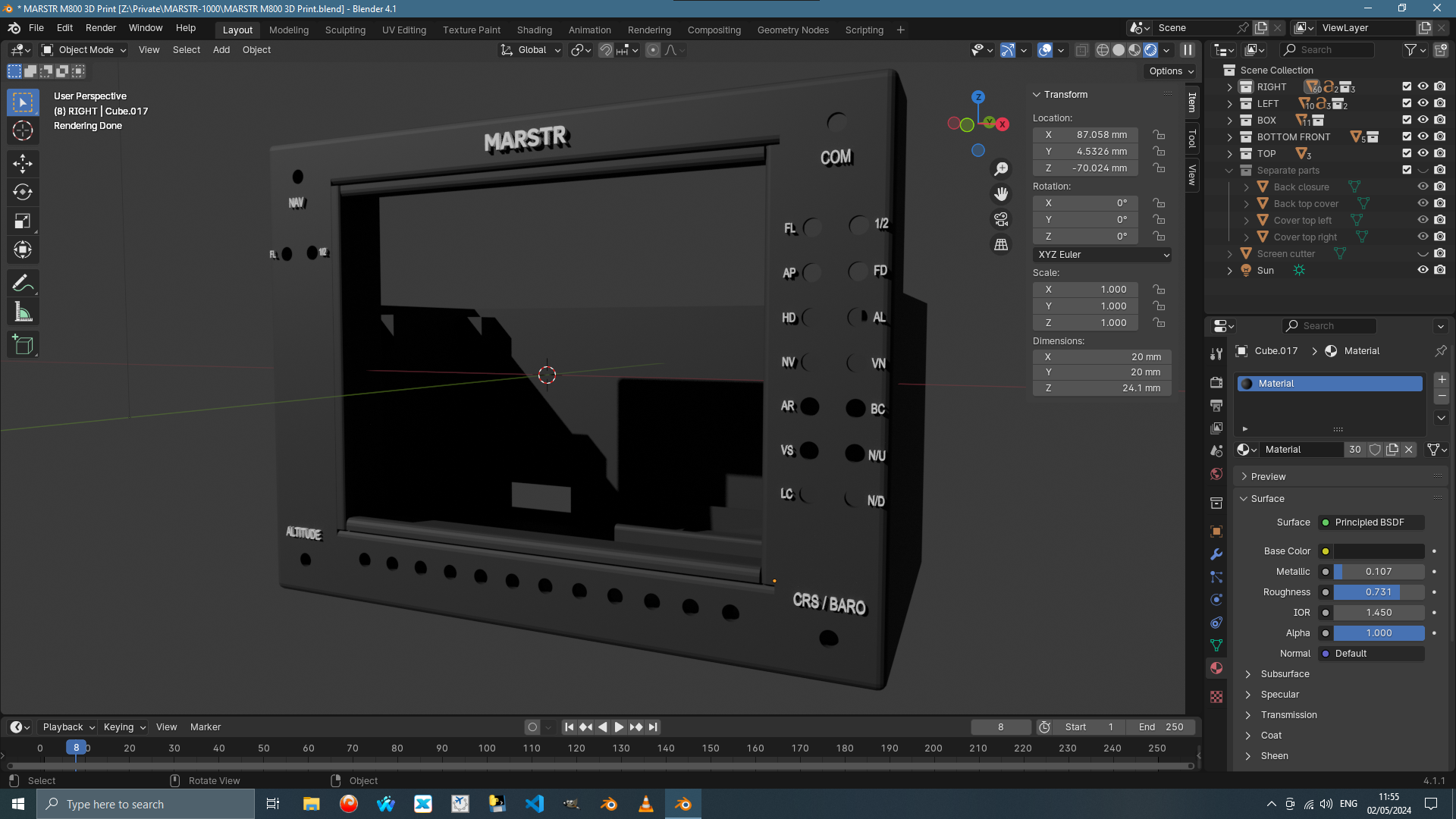

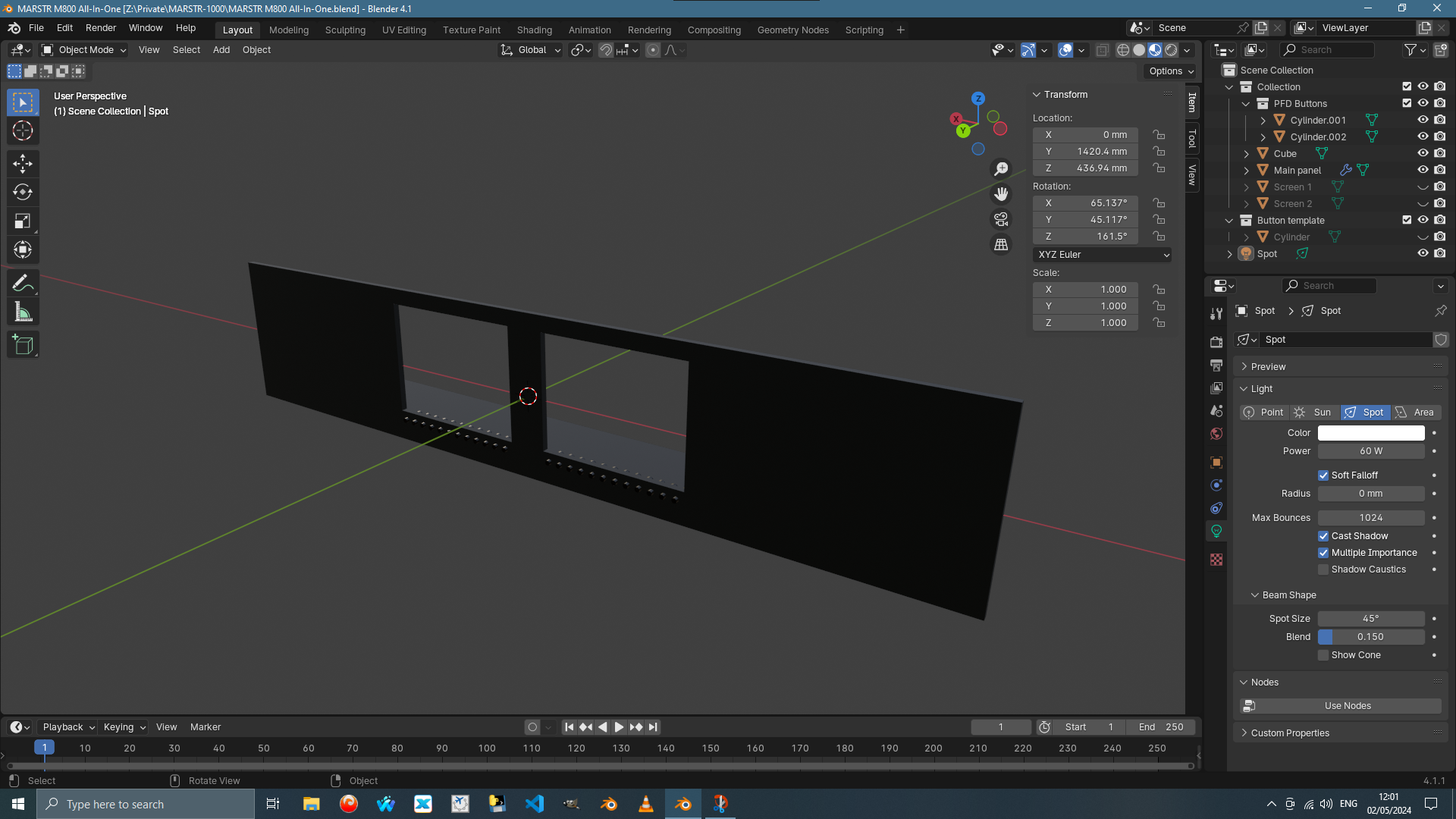

Building a custom cockpit - Part 1 DIY Shortly after seeing this video (Link), I felt inspired to build my own variation of this. I could just copy what's in the video - but I'm limited in space, so I need to build a slightly smaller version. Also, it should fit exactly on and in my desk setup. Originally, I was going to buy a few of the panels you can find here (Link) This is the list of what I want to achieve: - Custom avionics and switch/button panels - Must fit into desk setup - Ideally extensible or interchangable in components - Functions as some kind of keyboard emulator or actual controller with buttons and axes - Buttons and switches must be mappable to their assigned use with the flight simulator (but could be used in other software) I already knew soldering will be involved in this project and there are no two ways around it. So an opportunity to get skilled in that area as well. I first designed the flight displays in Blender, applying values of the material that I will most likely use: MDF 6mm thick plates. These will be held in place by screw placement in different positions, ultimately creating the case of each unit. Here's an initial design of a box, made for my desk and made of 6mm thick wooden material:  The yellow bits are placeholders for screws. While this design does work, it is limited in space, consists of quite a number of smaller custom-cut parts, I could not find any service online that will cut parts to size this small. So I had to discard this kind of design. Next, 3D printing. In the video I linked above, a 3D-printed replica of the Garmin G1000 exterior is used. While I cannot use units this large, I could come up with a similar design for 3D printing, assemble it, and build my unit. Here's my 3D print design:  This is what it would look like assembled - each part can be printed separately, and then put together. It looks real neat, even has a designated area for the Arduino in the back, plus a gap for the cables... It turns out that using even the cheapest 3D printing service I could find near me, this case would cost me about 200 Euro - and I would need two of those. And to be honest, I am not ready to spend this much money. So... I went back to square one but came up with probably the best idea: build a panel that has everything - along the entire width of my desk. Or to be more precise, along the length of my monitor stand. It turns out the service I initially found that can cut wood to size, will accept my sizes and cutouts. A look at a draft:  The huge gaps are obviously for the LCD panels. The buttons for the below the displays do fit nicely. This design gives me quite a lot of design freedom and is not as limited as the other two - plus, I will fare a lot cheaper with that one large piece, than the other two designs. DIY items: - 8 inch LCD Screen with display driver unit x2 : (Link) - Pack of black momentary push buttons: (Link) - Soldering iron station: (Link) - Helping hand: (Link) - ELEGOO Mega 2560 R3 x2: (Link) - Keyestudio Prototyping Plates: (Link) - Header pins: (Link) - Cables for soldering: (Link) Pack of small cable ties to keep the cabling clean inside the housing: (Link) As you can see, all of these combined aren't too expensive. Let's build this thing. |